We offer a comprehensive range of advanced water and wastewater treatment packages designed for industrial and municipal applications. Each package is engineered to deliver high efficiency, operational reliability, and full compliance with international standards. Our turnkey systems are developed to optimize performance, reduce operational costs, and support sustainable water management.

Explore our products below to learn more

about their features and applications

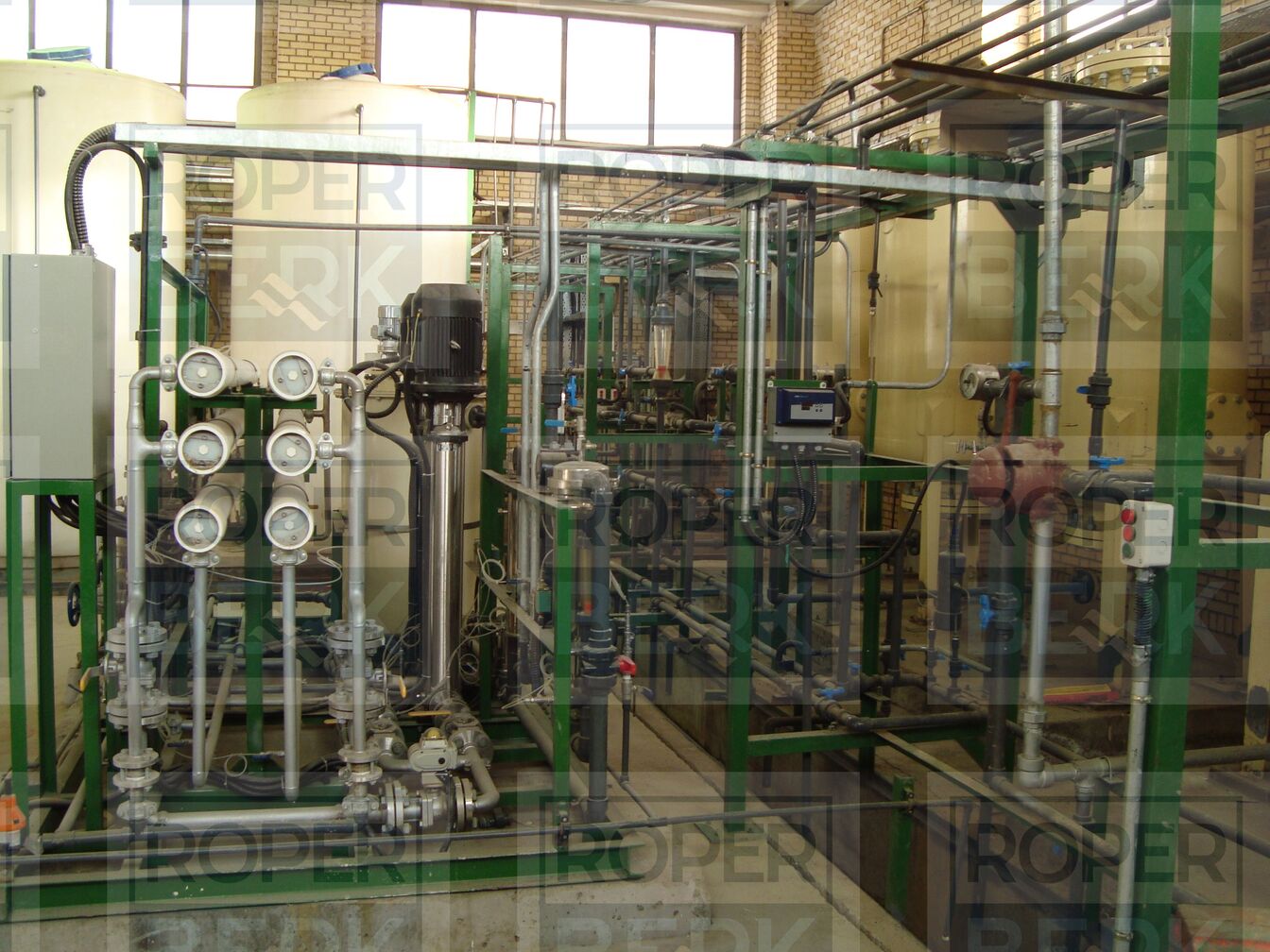

Reverse Osmosis (RO) is an advanced membrane technology that uses high pressure to pass water through a semi-permeable membrane, removing ions, dissolved salts, heavy metals, microorganisms, and organic pollutants. It is widely used for producing drinking water, high-purity industrial water, boiler feed water, brackish and seawater desalination, wastewater reuse, and many industrial and municipal applications.

Electrodeionization (EDI) combines ion exchange and direct current to continuously remove ions, producing ultrapure water up to 18 MΩ·cm. Used after RO in pharmaceuticals, power plants, electronics, and laboratories. Preferred over traditional mixed bed for continuous operation without chemicals.

Demineralization (Demin) or ion exchange systems use cation and anion exchange resins to remove dissolved ions from water, producing very high-purity water. Applications include boiler feed, pharmaceuticals, power plants, electronics, and laboratories. Often used after RO or UF to polish water to conductivity below 1 µS/cm.

Ultrafiltration (UF) is a low-pressure membrane technology that removes suspended solids, colloids, bacteria, and viruses from water, while allowing dissolved salts to pass. UF is commonly used as pretreatment before RO, for drinking water treatment, industrial wastewater treatment, water reuse, and in food and pharmaceutical industries.

(Modular/Containerized Packages) are a new generation of water and wastewater treatment systems in which all components and equipment are assembled and tested in a modular manner in a standard chassis or container at the factory and transported to the project site. This approach has created a fundamental change in the speed of implementation, quality, cost and flexibility of water treatment projects.

Chemical dosing systems inject precise amounts of chemicals into water or wastewater streams. Used for pH control, scaling prevention (antiscalant), disinfection (chlorine, hypochlorite), fluoride removal, coagulation, and other treatments. Essential in industrial, municipal, and power projects.